Call: 07313726971

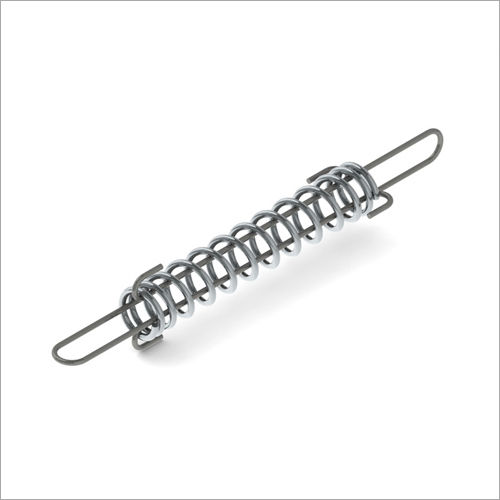

Drawbar Spring

Drawbar Spring Specification

- Capacity

- Customizable as per requirement

- Style

- Helical Compression

- Load Type

- Axial Load

- Material

- High Carbon Steel

- Wire Diameter

- 6 mm

- Surface Finish

- Polished, Anti-Corrosive

- Fatigue Test

- Guaranteed for high fatigue resistance

- Outer Diameter

- 35 mm

- Application

- Industrial, Truck, Tractor Drawbars

- End Type

- Hooked

- Color

- Metallic Silver

- Length

- Customizable

Drawbar Spring Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 50000 Pieces Per Month

- Delivery Time

- 2-3 Days

About Drawbar Spring

| Diameter | 18mm |

| Elongation At Break | 12% |

| Finishing Type | Polished |

| Hardness | 55 HRC |

| Length | 10 inch |

| Technique | Hot Rolled |

| Country of Origin | Made in India |

| Shape | Spiral |

| Packaging Type | Packet |

| Material Grade | SS304 |

| Usage/Application | In Drawbar |

| Material | Stainless Steel |

Customizable Drawbar Springs for Heavy-Duty Applications

Our drawbar springs are tailored for versatility and strength, serving an array of industrial, truck, and tractor applications. Each spring is crafted from high carbon steel, providing exceptional endurance against high fatigue. The polished, metallic silver surface ensures resistance to corrosion, while hooked ends deliver reliable attachment. With customizable length and load capacity, these springs meet unique operational requirements, making them a preferred choice for various dealers and manufacturers.

Advanced Manufacturing and Quality Assurance

Produced by experienced fabricators and suppliers throughout India, our drawbar springs undergo rigorous fatigue testing to guarantee high performance. Polished surfaces and anti-corrosive treatments protect against harsh conditions. Every unit is engineered for axial load support, providing dependable functionality where durability is essential. These springs are suited for traders, wholesalers, and retailers seeking premium components for industrial equipment.

FAQ's of Drawbar Spring:

Q: How is the drawbar spring customized to suit specific operational needs?

A: The drawbar spring's length and capacity can be adjusted based on the application's requirements. Clients can specify the preferred dimensions and load ratings, making the spring suitable for various trucks, tractors, and industrial machinery.Q: What materials and finishes are used for this spring, and why?

A: This spring is made from high carbon steel, chosen for its high fatigue resistance and durability. Its polished metallic silver surface is enhanced with anti-corrosive properties to ensure long service life in demanding environments.Q: When should these drawbar springs be considered for use?

A: They are best used when industrial, truck, or tractor drawbar systems require strong, reliable axial load support and enduring performance, particularly in settings where durability and corrosion resistance are paramount.Q: Where are these springs manufactured and supplied?

A: Our drawbar springs are manufactured and distributed throughout India by a network of dealers, distributors, fabricators, producers, retailers, suppliers, traders, and wholesalers.Q: What is the process for ordering a customized drawbar spring?

A: Customers can contact the manufacturer or supplier with specific requirements regarding length, capacity, and other features. The spring is then fabricated as per the specifications to ensure optimal fit and performance.Q: How are hooked-end drawbar springs installed?

A: The hooked ends are designed for secure attachment to drawbar assemblies. Proper installation involves aligning the hooks with mounting points, ensuring a stable fit that accommodates axial loads.Q: What are the main benefits of using these drawbar springs?

A: These springs offer high fatigue resistance, dependable axial load management, customizable specifications, and excellent anti-corrosive properties, making them a reliable choice for heavy-duty industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese